Bedrock Planes

If you’ve been using standard Stanley bench planes like the No. 3, 4, 5, 6, or 7 you might be wondering whether upgrading to a Stanley Bedrock (models 603–607 or others) is worth it. The short answer is: it depends on what you value in your tools. For many experienced woodworkers, the Bedrock series offers a noticeable upgrade in precision, performance, and long-term satisfaction. For others, it may feel like an unnecessary added expense.

Craftspeople from all over the world use the standard Stanley versions everyday and do great work with them. They are happy with these planes and do not see the need for Bedrock planes. If that is you, great, I just saved you some reading. But if you want something special and a little better or are just interested in learning about them, then read on.

In this article, we’ll look at several factors to help you decide whether upgrading is right for you or, if you’re new to woodworking, whether investing in Bedrock planes from the start makes sense.

I chose to upgrade based on a few key factors. Most of these reasons are discussed below, but primarily, I appreciate the improved adjustability, added weight, build quality, and aesthetic appeal of the Bedrock planes. Tom Lie-Nielsen selected this design as the foundation for his premium line of planes (subsequently copied by many other makers) for a reason. I avoid the earlier types of Bedrock planes, but any of the flattop types should be fine. My preference is from 1920’s types to end of production in the 1930’s.

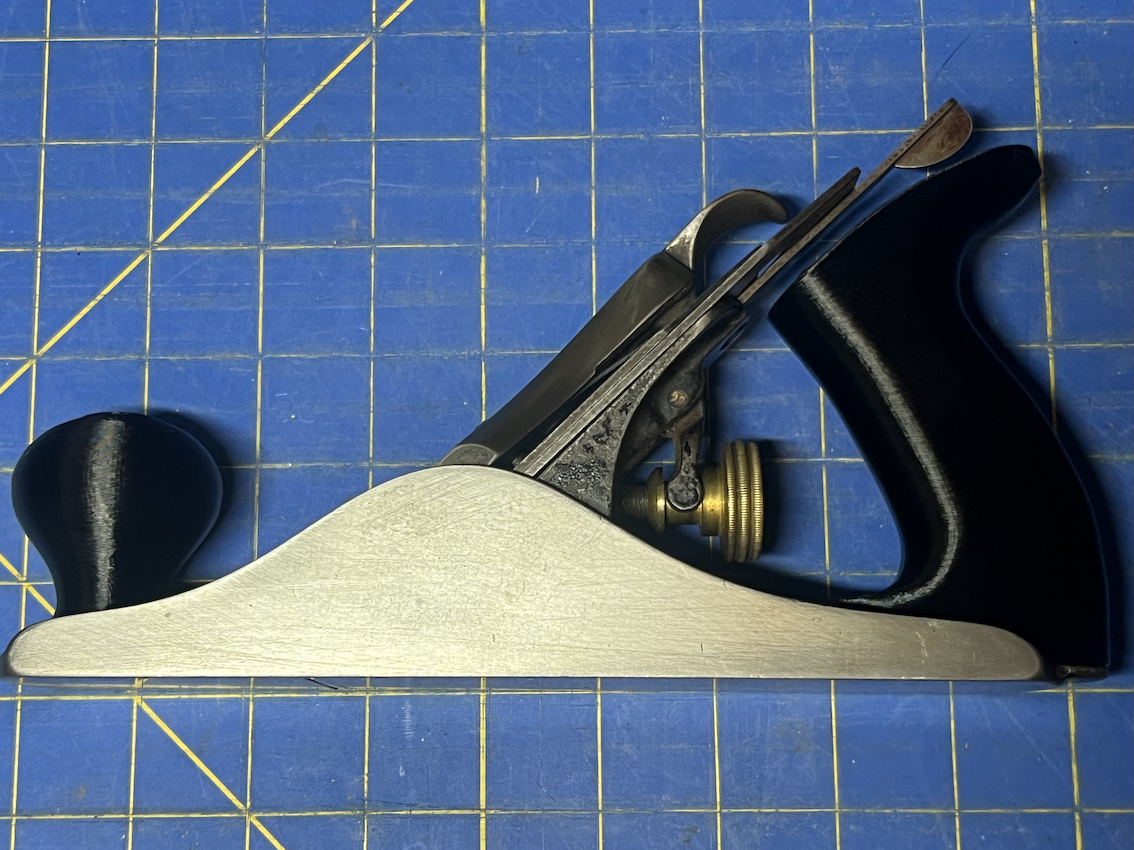

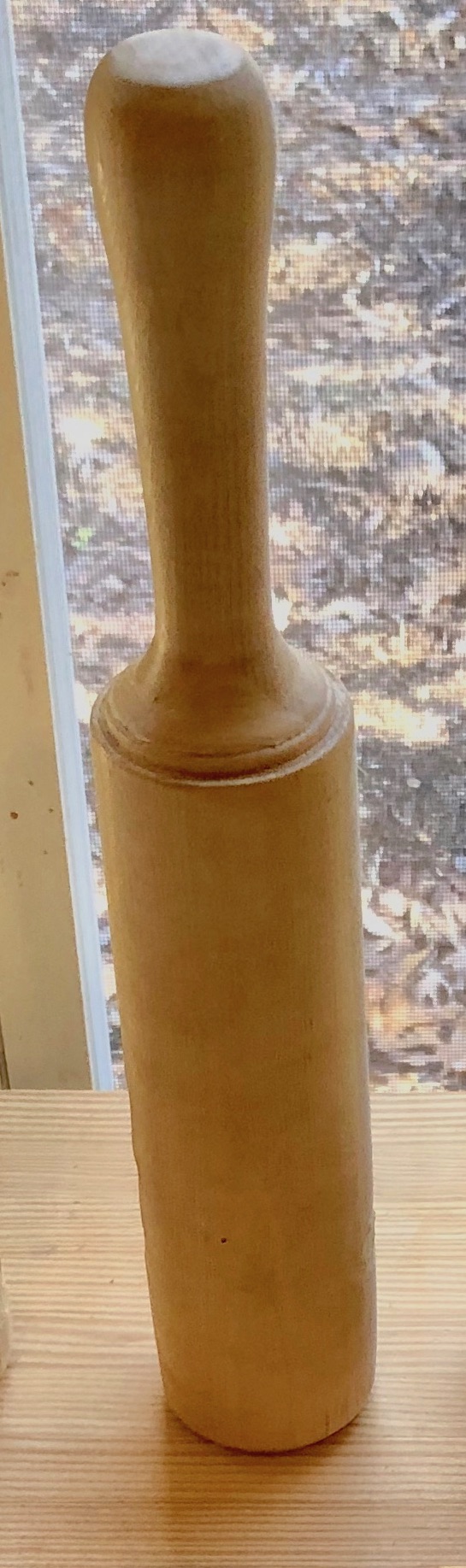

As you may see in the photo above, I have upgraded all the chip breakers and plane Irons with newer thicker ones. My two favorite are A2 Hock Blades from Lee Valley and CPM Magnacut from Lake Erie Toolworks.

You don’t need to upgrade your planes all at once, it’s perfectly fine to take your time. It took me about five years to acquire the ones shown in the photo. I’ve found some good deals and some fair ones, but I don’t think I ever overpaid, because I was selective about what I bought.

You probably don’t need the full range of planes from No. 603 to 607, but I personally use all of them—so upgrading all of my existing planes to Bedrocks was an easy decision.

If you’re just starting out, a 604 and a 605 make excellent entry points. From there, you can expand to a 607 or other sizes as your needs, budget, and availability allow.

1. Why Would I Want to Upgrade over regular Stanleys?

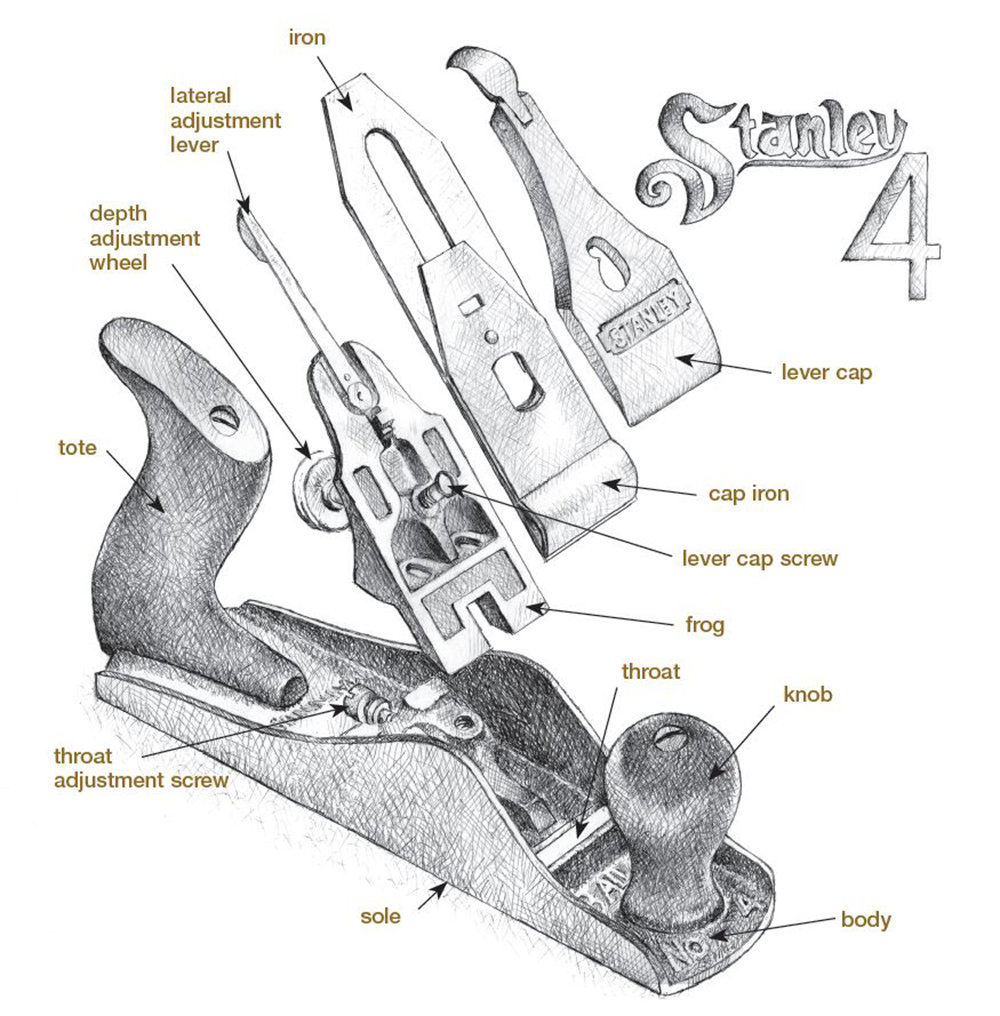

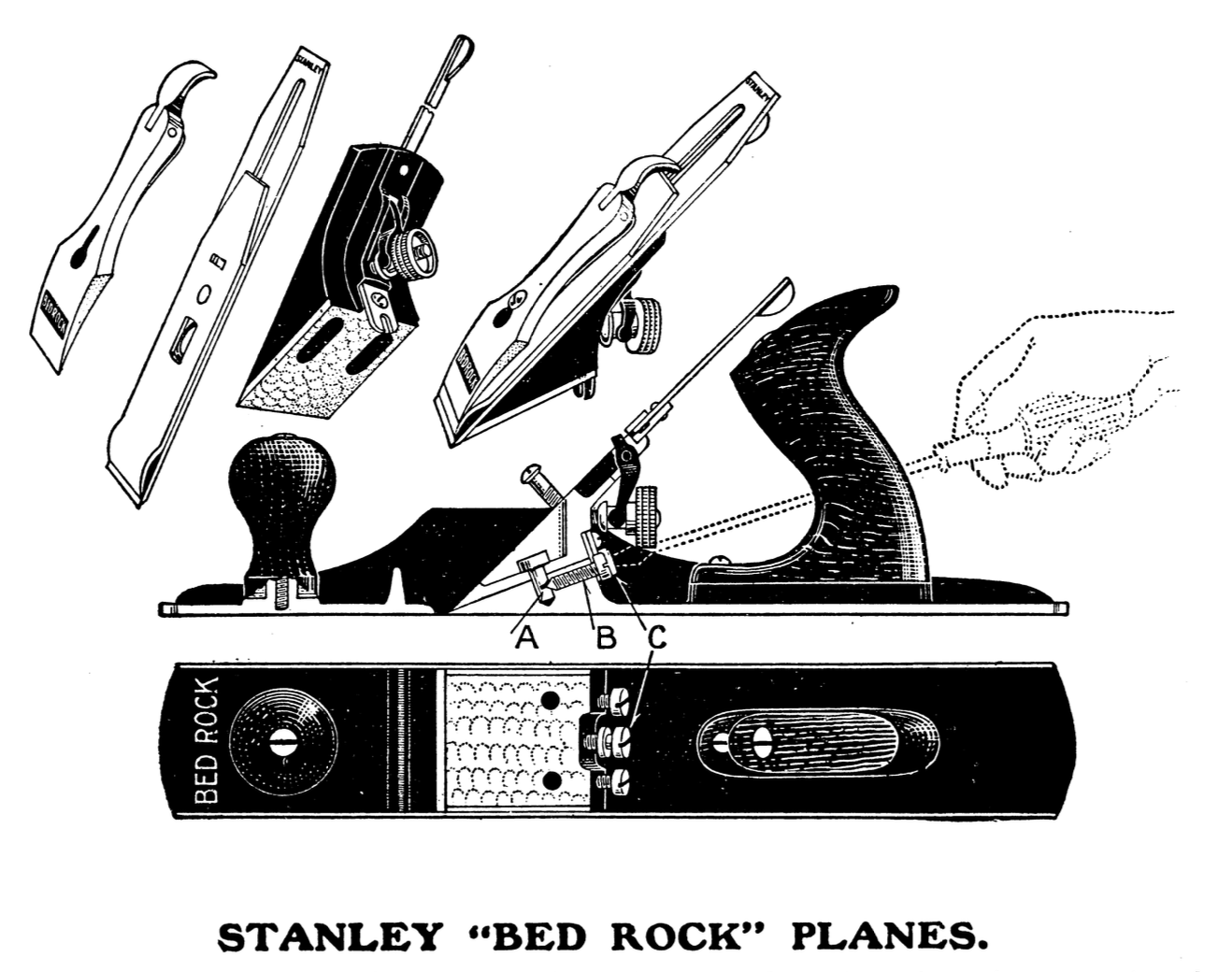

The Stanley Bedrock planes were designed as a premium line for serious woodworkers. Their improvements over standard Bailey style planes include:

- More stable frog design – Bedrock frogs sit on a wide machined surface, reducing chatter and improving blade support.

- Easier frog adjustment – You can adjust the frog (and mouth opening) without removing the blade, a big time-saver.

- Heavier castings – Adds mass and stability, especially noticeable on smoothing and jointing tasks.

- More precise machining – Leads to better registration and tuning.

- Collectibility and aesthetics – For many, owning a Bedrock is about history, pride, performance and they way they look.

Why the Stanley Bedrock Plane Feels Like a Single Solid Tool

The Stanley Bedrock plane stands out for its rock-solid construction. The frog sits in full contact with a precisely machined bed in the plane body, making the entire tool, from iron to sole, feel like a single piece of metal. This design virtually eliminates vibration during use.

The frog features a tongue-and-groove interface with the body, ensuring it remains square to the mouth and aligned during adjustments, no shifting, no wobble.

Two large-diameter pins secure the frog in place. These pins have tapered holes that align with tapered frog clamping screws. As the screws are tightened, they act like wedges, locking the frog down with exceptional rigidity. If the pins are removed, they must be reinstalled with the tapered holes aligned to the screw tips.

Adjusting the mouth for fine or coarse work is quick and easy. Just loosen the clamping screws, reposition the frog using the center adjustment screw, and retighten. No need to remove the iron or lever cap.

Finally, the contoured sidewalls of the Bedrock body aren’t just aesthetic—they add stiffness and provide excellent bearing surfaces for shooting work or side use.

The description of Stanley Bedrock Planes starts at Page 54 in the 1922 edition of the Stanley Catalogue No 34.

2. Where Can I Get Them?

Stanley Bedrocks are no longer in production, but they’re still relatively available but they were not produced in the numbers that standard Stanley planes were made as such they will be more expensive following the law of supply and demand, but they still can still be a much cheaper option than new premium planes:

- eBay – Best selection, but watch for inflated prices or poor condition.

- Tool Dealers – Sites like Jim Bode Tools, Just Plane Fun, Hyperkitten, or The Superior Works offer vetted tools.

- Facebook Marketplace or Craigslist – Be patient and picky. There are some real dogs out there and you don’t need anyone else’s problem plane.

- Estate sales and flea markets – Good deals can be found if you’re persistent.

- Online forums – Places like Garage Journal, Reddit’s r/handtools, and woodworking Facebook groups.

3. How Much Should I Pay for Them?

Prices vary by model and condition, but here are rough ranges for unrestored, usable Bedrocks:

| Model | Expected Price | Notes |

|---|---|---|

| 603 | $125–$200 | Smallest and often most expensive per size |

| 604 | $100–$180 | Popular smoothing size |

| 605 | $90–$160 | Common and great all-around size |

| 606 | $100–$175 | Mid-size jointer |

| 607 | $150–$250 | Desirable for edge jointing |

Tip: You can save significantly by purchasing planes that need cleaning and tuning, as long as they’re structurally sound—no major cracks, deep rust pits, or swapped parts.

Please note: Buyer beware! You can get great deals on eBay and other auction sites, but make sure the seller takes returns otherwise you may want to pass. Please inspect for any major pitting, cracks, damage, repairs or welds. Check for missing or wrong parts. Ask seller for more detailed photos if not provided. Educate yourself on what a complete and correct Bedrock should look like for the appropriate type.

4. How to Clean and Tune a Bedrock Plane

Please watch some of the video content for cleaning and tuning your planes before jumping in and doing it. These are very valuable planes from both a historic and a usage standpoint, so do research and please be respectful of their history. I used to be way more aggressive in my refurbishing of my old planes. As I have more experience, I now take a more minimal approach to getting these antiques into working order.

Restoring a Bedrock is very manageable. This is owner preference, but please keep in mind you are probably not the last owner of this plane. My preference is, I like to get the plane to usability and respect the tools long history as much as possible and preserve as much of it’s history for future owners to appreciate. Here’s a checklist to guide your process:

Cleaning & Prep

- Rust removal: I prefer Simple Green and 000 and 0000 Steel wool to retain some of the patina. I clean and oil all the metal hardware and am careful to avoid damage to the Japanning in the process. Use Evapo-Rust in extreme cases, but generally, these are not the planes you’re looking for. Heavily rusted barn finds for great deals may be an exception.

- Surface gunk: Scrub with simple green and a nylon brush or #0000 steel wool.

- Brass: This is very subjective. Some just clean the dirt off and call it good. I like bright brass. Even when cleaned bright it gets a nice color after a few years.

- Handles: Less is more here. Only in extreme cases do I refinish the handles and knobs, like if majority of the shellack or finish has cracked and come off and is not renewable.

Tuning

- Sharpen the iron: Use a honing guide and water/oil stones. Add a slight camber for smoothing planes.

- Check the sole: Use a straightedge; lap on granite or glass with sandpaper if needed.

- Check for square cheeks: Use a machinist’s square for registration surfaces.

- Adjust the frog: Move forward or back for fine or coarse work without removing the iron.

Parts

Sometimes you get the perfect plane but it’s got a cracked tote, knob or the lever cap has issues. All is not lost, you can find replacement parts and bring the value of your find up considerably by adding replacement parts.

- Just Plane Fun – Michael Jenks is a pleasure to work with and a wealth of knowledge.

- eBay – Purchase with caution from a reputable dealer

5. Resources for Learning More

Whether you’re learning to use a plane or restoring one, these resources are gold:

- Books: The Handplane Book by Garrett Hack; Planecraft by Hampton & Clifford, Handplane Essentials, Revised & Expanded. by Chris Schwarz

- YouTube Channels: Dave Corinth, Paul Sellers, Rex Krueger, Wood by Wright, Lost Art Press, The Plane Collector,

- Magazines: Fine Woodworking, Popular Woodworking (many back issues have detailed tutorials)

- Web: The Superior Works “Blood and Gore” site has detailed info on all Stanley models

6. Would a New Premium Plane Be a Better Choice?

If you want a ready-to-go tool with perfect machining, a new premium plane is worth considering—but it’ll cost you.

- Premium smoother: $300–$500

- Premium jointer: $400–$700+

Restored Bedrocks often match or beat this performance with a bit of work—and for much less money. But if time is more valuable to you than the restoration process, modern tools might be a better option.

7. Who Offers Modern Premium Planes?

- Lie-Nielsen Toolworks – Closest to the original Bedrock designs, built in Maine, USA.

- Veritas (Lee Valley) – Canadian-made, modern design with Norris-style adjusters.

- Bridge City Tool Works – High-end with a design-focused flair.

- WoodRiver – Affordable clones of Bedrock-style planes, decent for beginners.

- Cliffton Hand Planes – Very nice planes (But not as nice as Lie-Nielsen in my opinion). More expensive in the USA because of shipping than Lie-Nielsen.

Final Thoughts

Upgrading to a Stanley Bedrock plane is more than a practical decision—it’s a step toward precision, history, and a deeper appreciation of craftsmanship. If you find satisfaction in restoring tools and working with something that connects to over a century of woodworking tradition, the Bedrock upgrade is well worth the investment.

And remember, a little rust or grime isn’t a dealbreaker—it’s just the start of a good story.