There’s something very satisfying about driving a nail home or hitting a chisel with a mallet where you take just the perfect chunk of wood off. Mallets and Hammers offer the woodworker a great opportunity to make their own tools. At least this was the case for me. I have made several striking tools and I love using them. Woodworking mallets are simple to make and can last you a lifetime (more on that later). Good hammers are easy to re-handle and a joy to use. I have just a drop in the bucket of types of striking tools available to the modern craftsman, but every one of them gets plenty of use.

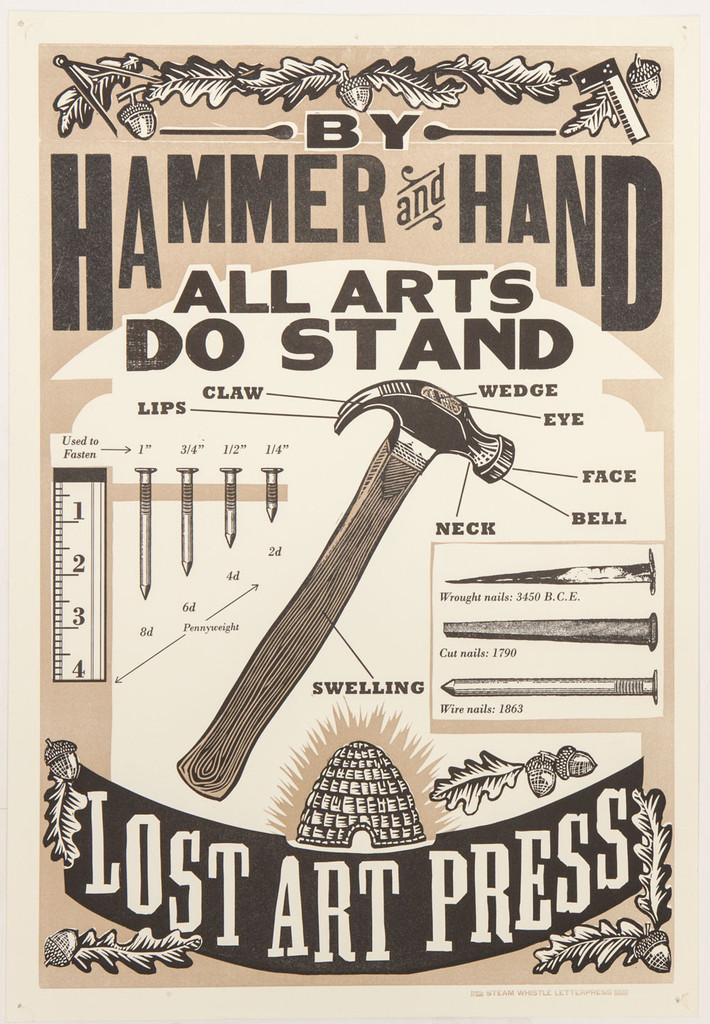

The nail on the magnet pictured on the left, is a nail I found at the homestead of my 5th Great-Grandfather. It’s a forged 18th century nail used in the construction of his first homestead in 1756. He would have recognized most of the tools in my current shop (the metal planes are “New” inventions, but he would know what they are) as hand woodworking tools have not changed all that much in the 270 years since then. I keep it next to my hammers to remind me of what came before and to keep in mind the ingenuity, resilience and fortitude of our ancestors.

“When you wish to make mortises, you begin by fastening the work on the bench with the holdfast and as close to the workbench legs as is possible so that the hammering has the strongest support for the cuts.”

Andre Roubo – With All The Precision Possible

Hammers

My hammers are used on every project. I’ve seen people with dozens of hammers, but I prefer to keep only the ones I need and will use regularly. My Vaughan 16 OZ Octagon Hammer is very nice. I bought it in 2012 from a local hardware store but it had a “singing” problem. Some hammers made with hardened steel sing or ring when struck. Some folks just accept it and others like me find it a bit annoying. I’ve looked for a solution for a while but I finally thought of a fix. Because it’s the claw that “sings”, I thought maybe some CA glue at the apex of the claw would dampen it. Sure enough it did, by about 70%. I can live with the reduced volume and it’s no longer a concern. I’m hoping the glue will not break off after lots of use, I’ll let you know it it does, but for right now I enjoying the softer songs it produces.

The 7 oz. Homemade Brass hammer (Jan 2015) was a really great addition to my hammer set. I blogged about it here and I have used it as my primary plane iron adjuster. It’s also used any time I don’t want the mar the surface of metal object I’m striking.

- Vaughan DO16 16 OZ Modified Octagon Nail Hammer

- Workforce 7 oz. with Hickory Handle

- Lie-Nielsen 4 oz. Hardened A2 Steel Cross Peen Hammer

- Homemade 7 oz. Brass Hammer with turned cherry handle

- Estwing MRW16BP Sure Strike 16 oz. Wood Handle Ball Peen Hammer

Mallets

There are myriad of different mallets for different uses. But I will concentrate on just the few types I own.

I made my first mallets in 2010 from hard maple I bought from the lumber yard. The first was a small mallet like the one pictured above, made from an article in an old wood-working magazine. I laminated the head from three pieces of the maple. I was using this first mallet in my first class at the Woodwright’s School making dovetails. While I was chopping out some wood the head exploded into 3 different parts (my understanding of gluing was still in it’s early stages). I embarrassingly looked around me to see if anyone noticed the mishap (I was at the rear most bench) and thankfully no one did. Only the handle survived.

It was about this time that I was able to get a stump from a maple that my Dad had cut down on the property where I grew up. I shaped this head and put in on the surviving handle and it has served me well ever since. I made a second small mallet just like the first except I used a solid piece of hickory rescued from my wife Beth’s childhood home. The hickory used to host a tree-swing in her childhood and gave her many happy memories, but the tree was toppled by a storm. I liked this mallet a little better as the Hickory was tough as nails and weighted more than the Soft Maple version. We have since started using the first mallet in our kitchen for pounding chicken breasts flat.

The second mallet I made was made at the same time and manner as the first “exploding” mallet and it is used for my heaviest tasks. It works great and time will tell if it has the same fate as the first. It has lasted 10 years, so I think I’m good.

The third mallet is a Estwing 12 oz. Soft Face Mallet. I use this as a “dead blow” mallet even if it’s not really one. I like its weight and it does the job I need done. Granted I haven’t done any really “big” jobs that need that kind of persuading (except the Split-top Roubo Workbench), so I may have to resort to an actual dead blow mallet in that instance.

Lastly, I have a Lathe Maple Mallet I use to pound mercilessly on my lathe center to set it into a turned piece. The mallet “takes a hit for the team” and gets damaged on every use to spare my center from being damaged.

- Small Soft Maple Head Mallet (replacement for the exploded mallet)

- Small Hickory Head Mallet

- Large Maple Mallet

- Estwing 12 oz. Soft Face Mallet with 12 in. Hickory Handle

- Turned Maple Lathe Mallet

- Roy Underhill’s “Impossible Mallet”

Sledges

What can you say about sledge hammers, they’re heavy and they “persuade” things to move. They are invaluable in splitting logs and processing raw timber. I have had the 4 lb. Sledge for probably 30 years and I do not remember where I got it. The 3 lb. Straight Peen Hammer was a more recent acquisition from a yard sale.

- 4 lb. Sledge Hammer

- 3 lb. Straight Peen Hammer

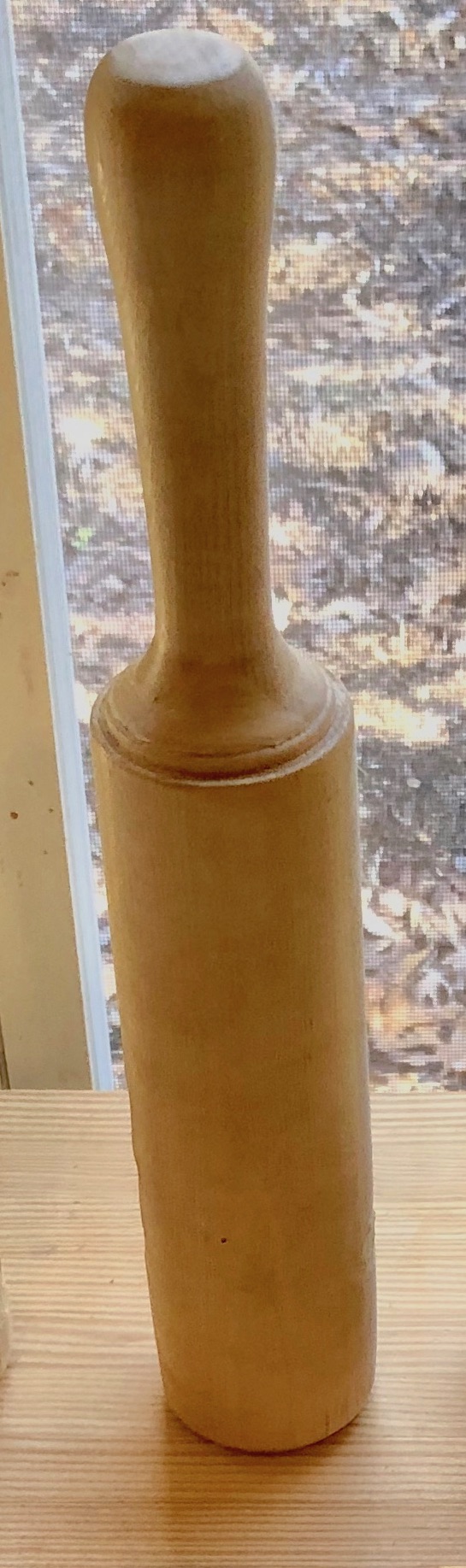

Batons, Gluts and Mauls

I only have one Baton, it’s used in my spoon and bowl carving kit. I turned this specifically for driving the meat cleaver I use for splitting wooden spoon blanks. It looks like a rolling pin with just one handle and that is probably what inspire me to give it this shape. Gluts and Mauls are usually made from tough wood stumps or tree sections.

Tools That Get Struck

Chisels (there are a lot of different types of chisels so I’ll create a dedicated blog about them in this “Tool Series”), Nail Sets, Steel and Wooden Wedges (not pictured). The Drawbore Pins are a couple of Craftsman Drift Pins that I pressed into service as Drawbore Pins. The nail set, punch set and wedges I’ve had for ages and could not tell you where I got them.

- Drawbore Pins

- Old Nail Set set

- Old Punch Set

- Steel Wedges

LN Standard Dowel Plate

Sm Modelers Vise, Narrow Gauge Rail Section Anvil, Iron Curved Anvil

Accessary Tools

Hammers hang out with a many different tools that help them do what they do. Dowel plates, vices and anvils, these are all tools that are used with my hammers. The Dowel Plate is exactly that, used to make dowels. Best used with green stock, the dowel plate can also be used with dried sticks. Just make sure to reduce the stick to a square or better yet an octagon to get the best results. This is a nice tool to have when you need just a few dowels of a specific size. The small vise is used in so many ways, I can’t list them here. The Narrow Gauge Rail Track Anvil came from my father in-law and its origin is from a small coal tunnel in Appalachia. The Small Iron Curved Anvil came from a yard sale. The anvils are used primarily for peening pins and rivets and also clinching nails.

- LN Dowel Plate

- Small Modelers Vice

- Narrow Gauge Rail Track Anvil

- Small Iron Curved Anvil

Please subscribe (on right hand side on computer and very bottom on phone) to the mailing list to get future blog updates.

Until next time, keep making shavings and sawdust.

Peace,

Aaron

Copyright 2021 © W. A. Henderson