A Perfect Mitered Dovetail?

Is there such a thing as a bad day in the workshop? I guess if you gouge yourself with a “pig sticker” or slice yourself with a knife, these could be considered bad days. This is not what I am talking about here.

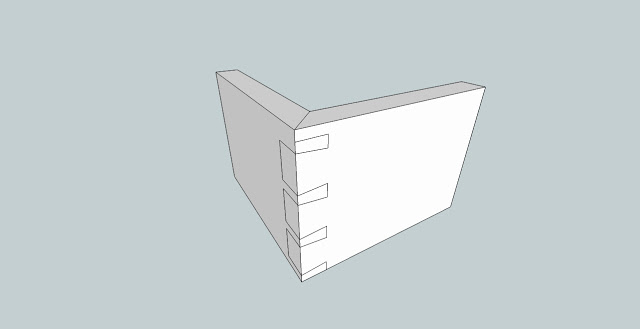

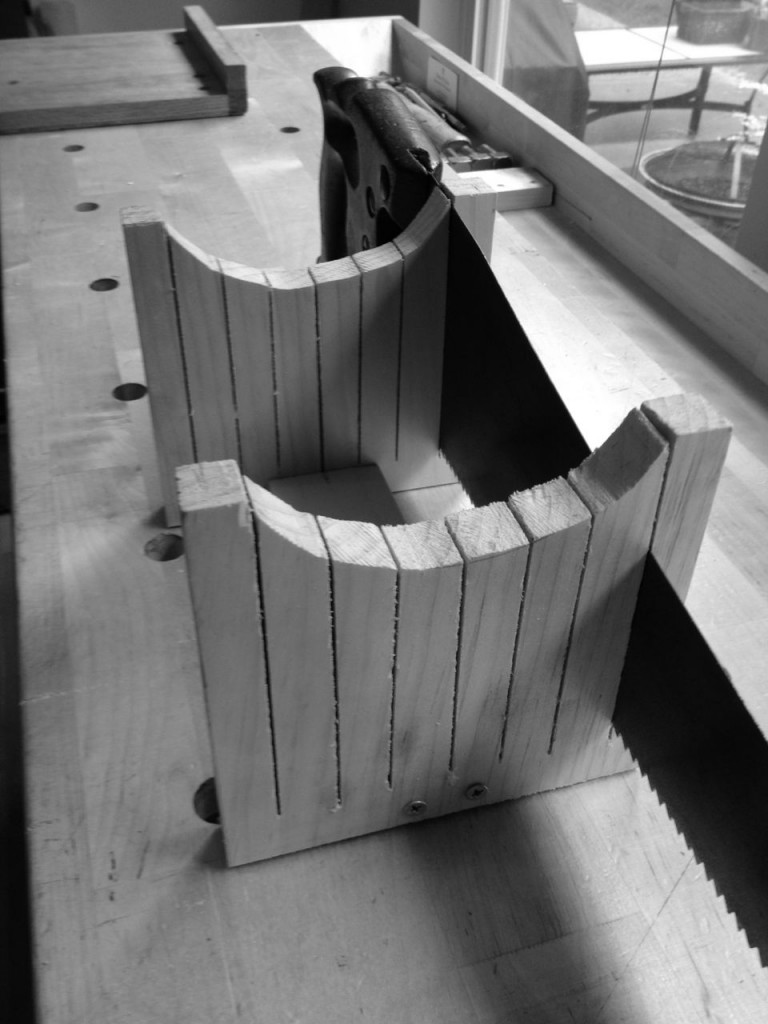

Some days, the good and the bad are not balanced, and you end up with more of one than the other. Yesterday was definitely one of those days. It all started out innocently enough. I’ve not had the opportunity to work in the shop for a few weeks…seemed like forever…but I wanted to continue with the moulding for my Saw Box. I had completed the shaping of two mouldings with my desired profile, and all I had to do was the mitered dovetails and wrap the bottom of the box – then I would be golden. As I had done this for the lid sans the molding profile, I felt pretty confident that I could do the same for the bottom skirt.

I proceeded to cut the two pieces of one on my moulded boards, and, because it had a knot in it, I could only use specific lengths. I had plenty of room for mistakes (or so I thought). I was going to put the pins on the opposite side of the main carcass (on the skirt this would be the short-end side), so I started laying out the joint of the short piece. Everything was going well up to the point where I started cutting the pins in the long piece….then I made a rookie mistake. I did not mark an X on my waste piece and I cut into the pin side of the pin and not the waste side.

I say “rookie mistake” because I did this exact same thing on my first dovetail at Roy Underhill’s Woodwright’s School in May of 2011. I even kept the miscut corner joint from the class as a “reminder.” Clearly I needed a refresher.

Ok, lesson learned, here is a new mantra: “Always mark your waste … ALWAYS.” After this mishap I thought: Well, this is my one “gotcha” today and everything should be ok, right? Wrong!

I had to cut a little more off than the width of the dovetail joint on the long piece of molding. I roughly measured the length on the Saw Box to make sure I had enough material and proceeded with my second attempt at the joint. I was set now as I had just cut the most beautiful, best fitting and square dovetailed miter joint known to man! I took it over to my Saw Box, put it up against the side, and said to my friend, Bob, jokingly: “I sure hope it’s long enough.” It was short by about 3/16 of an inch. How my heart sank. This meant that I not only had to redo the dovetail, but I also had to create a whole new moulding piece.

Oh the Sorrow!

Second newbie mistake of the day: “Measure twice and cut once.” Wow, I was batting a thousand. You would think given the way this day was going I would quit there, but no; I had to forge on. I haven’t had much time to get in the workshop lately, and I had to make the best use of my time. I decided to at least cut out the material and form my new moulding before quitting for the day.

I had a 2×12 board that had a knot-free edge wide enough for the ~2 inch board I needed for the moulding. I marked it with my marking gauge and proceeded to cut it out with my trusty old Disston rip saw. I normally like to cut my pieces a little wide and plane them down to size because my hand ripping is not the most accurate…but it was getting late and I decided to rip close to the line. At first glance, it looked like I finally did something right, but upon closer inspection I noticed I had angled my saw such that I was within the line on the top but shy on the bottom.

Third and final lesson of the day: “Do not take shortcuts on clear materials.” It’s ok to experiment on crappy material to try to improve your technique, but if you are unsure of an operation, do not try it on a nice piece of wood just to save time.

Given all the above, I think I should have stopped after the second problem and walked away for a while to reflect on what I was doing. I was also lucky I did not injure myself. It is hard to walk away, as I really enjoy my woodworking time, and I like to take full advantage when I can. But the price paid could have been more than just wasted time and material.

This makes me think about the adage: “A bad day in the workshop is better than a good day in the office,” well maybe not always.

-Aaron